Screen Printing: Everything from 153 Expert Interviews

This article isn’t just based on theory because many other blogs on screen printing do a great job at describing screen printing in theory.

For this piece, we have interviewed more than 153 screen printing experts across USA and Canada to really unearth the best and the worst of screen printing in real life scenarios.

All the experts we interviewed have had at least 10 years of experience using screen printing (as well as other imprinting methods), and have imprinted on both hard goods like drinkware as well as soft goods like apparel and garments.

Throughout this blog, you will see experts advice, experience, and suggestions on the following topics:

1. Introduction to Screen Printing

Description of Screen Printing

How Does the Screen Printing Technique Work

Screen Printing Steps

2. What is Screen Printing?

Screen Printing Definition and Basic Concept

Screen Printing: Perfect For

Quick Facts About Screen Printing

Comparison with Other Printing Methods (Digital Printing, Heat transfer)

Screen Printing vs Digital Printing

Screen Printing vs Heat Transfer Printing

Expert Advice on Screen Printing VS Heat Transfers

Key Components (Silk Screen, Ink, Squeegee)

The Silk Screen

The Ink

The Squeegee

5 Interesting Screen Printing Facts

3. Why Is Screen Printing Used?

Durability and longevity of prints

Quality of Printing

Lifespan

Cost-effective

4. Where is Screen Printing Used?

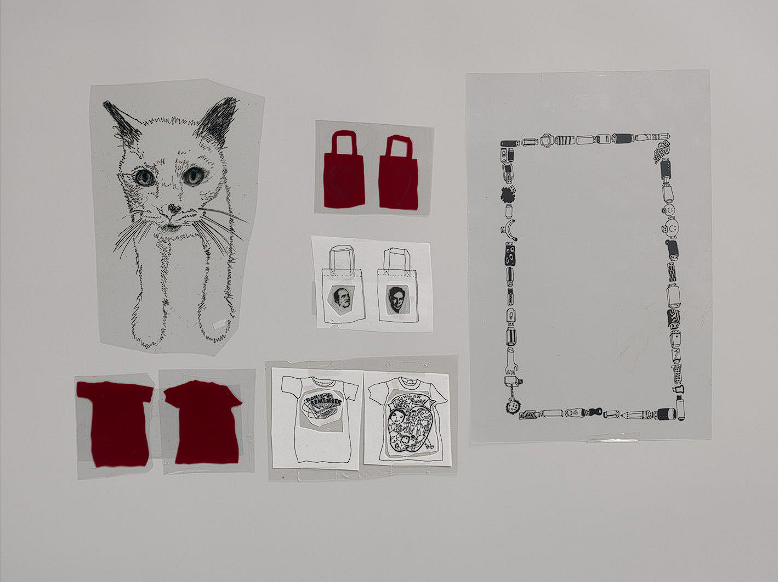

Apparel (t-shirts, hats, sweatshirts, hoodies,etc.)

Promotional items (bags, keychains, mugs, tumblers, etc.)

5. Different Types of Screen Printing

Spot Color Screen Printing

Halftone Screen Printing

4 Color Process Printing- (CMYK)

Grayscale Printing

Simulated Process Screen Printing

6. The Advantages of Screen Printing

Handling Big Orders is a Breeze

It Works for Any Design

Made to Last

Looks Awesome

Simulated Process Screen Printing

7. Screen Printing Problems and Solutions

Screen Printing Image Concerns

Bubbling: Air Bubbles on Solid Prints

Contamination: Unwanted Spots in Your Print

Ink Spreading: When Edges Aren't Crisp

Ink Leakage Around the Image

Blur and Ghosting Effects

Blurred and Distorted Images

Addressing Streaks in Screen Printing for Consistent Image Quality

Tackling Mottling for Uniform Ink Absorption

Preventing Ink Drying in Screen for Flawless Printing

Ensuring Complete Ink Coverage in Multicolor Prints

8. The Future of Screen Printing

Historical Context and Evolution

Screen Printing History

European Debut of Screen Printing

The Boom of Screen Printing in the 1960s

Screen Printing Now: How Things Are Today

The Importance of Screen Printing in Today's Market

Screen Printing Statistics

Is the Screen Printing Industry Growing?

Exploring Global Screen Printing Industry Statistics: Insights from Different Regions

North America

Europe

Asia Pacific

Global Screen Printing Market Expected to Reach $11.2 Billion by 2030

The U.S. Screen Printing Market Is Valued at $952.6 Million, with China Projected to Grow at a 22.5% (CAGR)

Exploring the Future of Screen Printing in the Growing Digital Landscape

Technological Innovations Keep Screen Printing Competitive Amidst Digital Printing's Growth

Pre-Press for Screen Printing Made Simpler Than Before

What is the future of screen printing?

9. How Screen Printing Works: A Step-by-Step Guide to Design Creation Conceptualizing and Digitizing

Screen Printing Process Step By Step

Step 1. Design Creation

Step 2. Screen Preparation

Step 3. Exposing the Emulsion

Step 4. Creation of the Stencil

Step 5. Printing the Design

Step 6. Heat Curing and Finishing

10. 43 Frequently Asked Questions (FAQ) Section

What is the estimated value of the Global Market for Screen Printing?

What is the growth rate of the Global Market for Screen Printing?

What is the forecasted size of the Global Market for Screen Printing?

What will be the CAGR of the screen printing market?

Which region will lead the market?

What are the major factors driving the screen printing market growth?

What is the best angle for screen printing?

What is the angle for screen printing?

What is the minimum thickness for screen printing?

What is the best size for screen printing?

How much pressure do you apply when screen printing?

What is the standard mesh size for screen printing?

What are the parameters of screen printing?

What is the best temperature for screen printing?

What size dot for screen printing?

Which garment decoration methods are most recommended for clients?

Can you explain the distinctions between screen printing, sublimation, and transfers?

How are embroidery and screen printing most commonly priced?

What kind of artwork is required by a distributor for each type of decoration method?

Why does the cost of screen printing increase for dark-colored garments?

Will screen printing ink wash out?

How long does screen printing last?

Can screen printing be done on any material?

What is the process of screen printing?

Is screen printing good quality?

Why is screen printing so expensive?

What material is best for screen printing?

Is screen printing permanent?

Does the screen print crack?

Can you screen print on 100% cotton?

What are the main features of screen printing?

How many types of ink are used for screen printing?

Can cotton be screen printed?

Which fabric is suitable for screen printing?

Which film is used in screen printing?

What are the three types of screen printing presses?

What are the characteristics of screen printing?

Does screen printing require heat?

What are the 4 colors in screen printing?

What is CMYK screen printing?

What is the frequency of screen printing?

How much water does screen printing use?

What's the difference between screen printing and digital printing

1. Introduction to Screen Printing

Description of Screen Printing

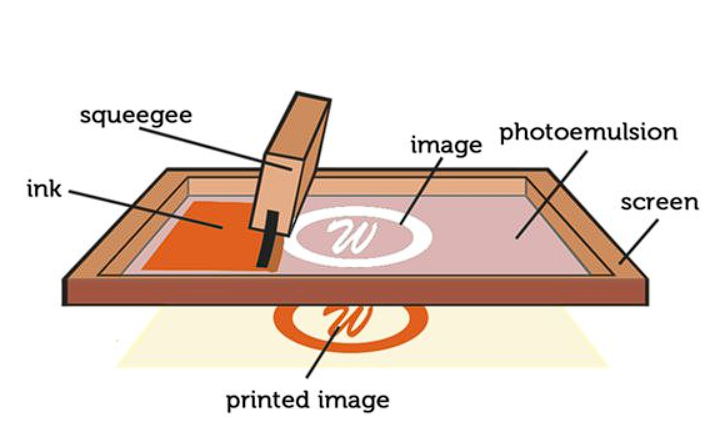

Screen printing, or silk screening as some call it, is a way to put pictures or designs on products like apparel (t-shirts, hoodies, sweaters, etc.), drinkware (mugs, bottles, tumblers, coasters, etc.), tech products like power banks, speakers, etc., and promotional products. It uses ink or dye, a metal screen with tiny holes, and a squeegee (a tool to spread the ink). This way, items like corporate gifts or company swag can be branded and made unique by putting logos or personalized text on them easily.

How Does the Screen Printing Technique Work?

You push the ink through the screen onto the item you're printing. For each color in your design, you use a different stencil to make sure the ink goes exactly where it should. This is how you get those cool images onto all sorts of products.

Screen Printing Steps:

1. Stencil Creation: Create a stencil by putting the design on a fine mesh screen.

2. Ink Application: Use a squeegee to push ink through the stencil onto the printing surface.

3. Layering and Drying: Add different colors one at a time, let each layer dry, and you'll get the final design.

Screen printing is a super popular way to put designs on blank stuff, apparel like t-shirts, hoodies, hard goods like mugs, bottles, and much more. Why? Because it’s quick, doesn’t cost a lot, and you can do a ton of them at once!

2. What is Screen Printing?

Screen Printing Definition and Basic Concept

The screen printing technique is a method of printing where a mesh is used to transfer ink or dye onto a surface, except in areas blocked by a stencil. A blade or squeegee is moved across the screen to push ink through the open areas of the mesh. Then, pulling the blade back causes the screen to touch the surface briefly along a line. This action allows the ink to soak into the surface and be pulled through the mesh openings as the screen springs back after the blade has passed. To create an image or design with more than one color, you print one color at a time, using separate screens for each color.

While paper and fabric are the most common materials on which people screen print, you can actually use metal, wood, and plastic too. One of the biggest reasons you would love screen printing is because you can choose from lots of colors to make your design just right. Plus, you can get PMS matching so your brand colour can exactly be matched in the imprint.

Screen Printing is Perfect For:

Quick Facts About Screen Printing

“A T-shirt with screen printing can last for about 40-50 washes.”

“The best materials for this kind of printing are cotton, blends of cotton, and polyester. (Just a heads up, it doesn't work well on coated fabrics.)”

“You'll get really bright colors and sharp edges with screen printing.”

“It works best if your design is simple, like one or two colors (since adding more colors will bump up the price).”

“If your design is super detailed or complex, screen printing might not be the best option.”

Comparison with Other Printing Methods (Digital Printing, Heat Transfer Printing)

Screen Printing vs Digital Printing

| Screen Printing |

Digital Printing (DTG) |

| Traditional method that requires stencils for printing. |

High-tech, akin to an inkjet printer but for fabric, printing designs directly onto the textile without needing stencils. |

| Capable of vibrant, solid colors using inks. |

Uses CMYK printing, resulting in slightly less vibrant colors due to the dot-based color application. |

| Best for simpler designs due to stencil use. |

Excels with complex, colorful, or detailed designs, including photographic images, without color limitations. |

| Typically involves a longer setup, making it costlier for small orders. |

Easy and quick setup, making it cost-effective for small batches or single items. |

| Can create textured and raised effects on prints. |

Lacks the ability to create textured or raised effects, offering a flat print surface. |

| Suited for large orders requiring durable, vibrant prints. |

Perfect for small orders or one-offs, with detailed or color-rich designs not suitable for traditional methods. |

Screen Printing vs Heat Transfer Printing

| Screen Printing |

Heat Transfer Printing |

| Uses stencils and ink to apply designs directly to the fabric. |

Utilizes heat-sensitive adhesive on transfer paper to transfer designs onto fabric through pressure and heat. |

| Better suited for larger orders due to setup requirements. |

Cost-effective and easy setup, ideal for small batches or custom prints. |

| Can be challenging for highly detailed images. |

Excels at transferring detailed and photographic images onto fabric. |

| Best for flat surfaces and standard textiles. |

Highly versatile, capable of printing on various items like bags, hats, and shoes, even with awkward shapes. |

| Prints are typically more durable and wash well. |

Durability can vary; some prints may crack or fade with extensive washing. |

| Great for bulk orders needing solid, vibrant prints. |

Perfect for personalized or small quantity orders, especially on items that are tricky to print on with other methods. |

Expert Advice on Screen Printing VS Heat Transfers:

“My preference is always to go with screen printing unless there is a compelling reason to go with heat transfer. Screen printing looks crisper, doesn’t feel like a sticker stuck on the garment like heat transfers sometimes do, and costs less most of the time. But if the design is extremely complex and heat transfer would deliver the best quality, then I am not opposed to going with it.”

Anup Gupta

President

Cuyahoga Falls, Ohio

"Screen printing, 100 percent! I only offer HTV if the quantity if six to 12 pieces and any time a shirt is going to be worn only a few times. Your customers will thank you and will come back to you any time they need custom-printed apparel."

Kassi Porter Fuhrman

Owner

Shawnee, Kansas

"Go with a direct screen print, as it is simply more durable. Reasoning: ink to paper/paper to garment versus ink to garment. Nothing is lost in translation."

Donna LoPinto

Owner and President

Tarrytown, New York

"I do both in my shop. I agree with others that screen printing lasts forever (when done correctly). However, a good transfer applied correctly will last years and years of wash and wear. If it were me, and I do prefer the direct screen, I would do a transfer for this job. Beware of digital print transfers; always go with a truly fully screen-printed transfer. Lots of the companies try to sell you on a part-digital and part-printed transfer—do not get that! They are gross and plasticky!"

Brooke Bradley

Owner and Operator

Santa Maria, California

Key Components (Silk Screen, Ink, Squeegee)

To get a nice, clear print, a screen printer must have the right tools. Let’s look at all the equipment used in screen printing and explain what each tool does during the printing process.

The Silk Screen

i. Made with metal or wood frames.

ii. Mesh fabric, usually polyester, is stretched over the frame. It's cheaper and works as well as silk.

iii. Mesh thickness and thread count vary based on what you're printing on, for clear, detailed prints.

iv. To prepare, the screen is coated with emulsion and exposed to light, turning it into a stencil.

v. The best part? You can wash and reuse the screen for new projects.

The Inks

i. Ink Selection: Beyond color, choosing the right ink can add unique effects like sparkle, texture, or 3D appearance.

ii. Fabric Compatibility: The choice of ink is influenced by the fabric type to ensure optimal print quality.

iii. Durability for Clothing: Special inks are used for apparel to prevent fading after washing, ensuring long-lasting designs.

The Squeegee

i. A squeegee combines a rubber blade with a handle, which can be wooden, metal, or plastic.

ii. Its main job is to push ink through the mesh screen onto the printing surface.

iii. hoosing a squeegee size that matches the screen frame ensures even ink coverage.

iv. For detailed designs, a harder rubber blade is key to reaching small spaces.

v. On simpler designs or fabric, a softer rubber blade is preferred for its flexibility.

5 Interesting Screen Printing Facts

1. Screen printing's history extends back to the Song Dynasty, utilizing human hair for its durable yet fine mesh.

2. A 20th-century breakthrough with chromic acid salt-sensitized emulsions revolutionized screen printing with photo-imaged stencils.

3. The first promotional T-shirt, created for "The Wizard of Oz" premiere in 1939, showcased screen printing's versatility.

4. World War II saw screen printing's expansion into propaganda posters, military apparel, and aircraft decals production.

5. Andy Warhol, a prominent figure in the Pop Art movement, championed screen printing for its precision and ease of mass production.

3. Why Is Screen Printing Used?

Durability and longevity of prints

- Wide Range of Materials: Can print on anything from plastic to wood, including 3D objects.

- Color and Texture Handling: Excellent at printing vibrant colors and clear details on both light and dark backgrounds of any shape or size.

Quality of Printing

- Top-notch Design Precision: Ideal for logos or graphics, ensuring they stand out with crystal-clear sharpness.

- Better than Direct-to-Garment: Does not depend on dot mixing for color, leading to higher detail and color accuracy.

- Crisp and Clear Results: Maintains the sharpness and vibrancy of your designs consistently.

Lifespan

- Silk screen printing stands out for its durability.

- The ink and process used in screen printing create a strong bond with the fabric.

- Your designs remain vibrant and clear, enduring through numerous washes and daily use.

Cost-effective

- While the initial setup for screen printing can make it more expensive for small orders due to the need for separate screens for each color, it becomes exceptionally economical for larger orders.

- The cost per item decreases significantly with volume, making screen printing a budget-friendly option for bulk purchases.

4. Where is Screen Printing Used?

Screen printing is a favorite technique in lots of different fields because it's pretty straightforward to do. The fashion world, especially, loves using it for all sorts of fabrics like silk, cotton, and polyester. It doesn't stop there, though. Things we use around the house, like sofa covers, cushion covers, curtains, sheets, and other linens, are often made with screen printing too.

Let's explore additional opportunities for employing silk screen printing

T-Shirts

Hats

Sweatshirts

Hoodies

Bags

Keychains

Mugs

Tumblers

Bottles

Coasters

5. Different Types of Screen Printing

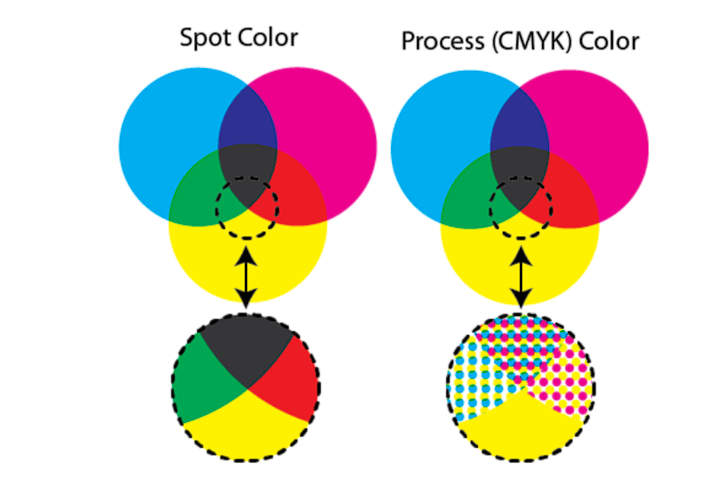

Spot Color Screen Printing

Spot color screen printing is super popular for making t-shirts. It's all about using the ink straight from the bottle, pushing it through a stencil onto the mesh screen to make bright, solid colors pop out. Sometimes, the ink ends up being thicker, which depends on what kind of ink and screen you use. This method is really good for getting bold colors to show up on dark shirts. Plus, it's the cheapest way to go if you're working with one to four colors. But, if your design has got like five to eight colors, you might want to look into something called simulated process to save some hassle with setting things up. Spot color is perfect for simple logos that don't need any fancy color fades or a ton of different colors.

Half-Tone Screen Printing

(Credit: Catspitproductionsllc)

Halftone screen printing is all about playing with colors in a smart way. Imagine taking just one color of ink and making it look like you've got two or more shades of that same color on your shirt. It's like magic, from a bold, full color to a super light version, kind of like a trick called "spot and dot." It's a cool trick for when you want your shirts to look like they're bursting with colors but without spending a ton of money. Let's say we put red on a white shirt and then add a bit of a fade-out effect with that same red. That faded part mixes with the white of the shirt and suddenly, you've got pink showing up. So, you end up with a shirt that looks like it's got red and pink on it, but guess what? You only used one screen and one color of ink. If the person designing your graphics knows their stuff, they can make your designs look super fancy using this trick. Plus, it means you don't need as many colors or screens, and the print on the shirt feels softer.

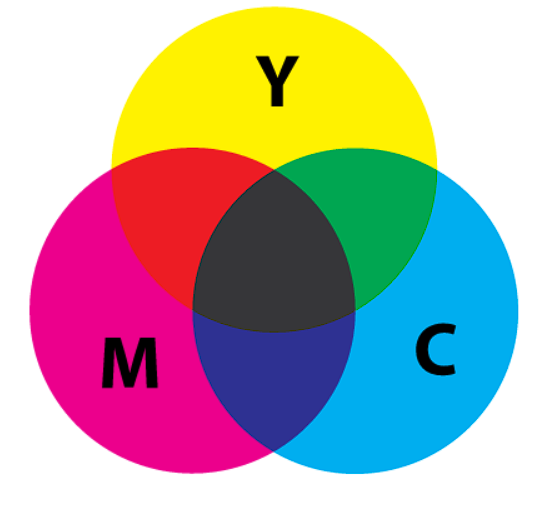

4 Color Process Printing- (CMYK)

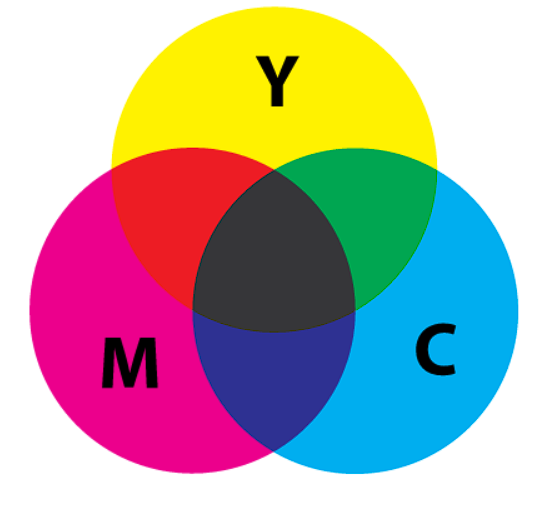

Printing on T-shirts, especially with full colors, is a bit of a crafty adventure, best suited for those big, automatic machines. You know, the kind that does everything with a push of a button. Trying this on a hand-operated press? Possible, but the magic really happens when you let the automatic press take the wheel. Here’s how it goes down: we start with a colorful picture and split it into its basic colors – cyan, magenta, yellow, and black. It’s like breaking down a rainbow into pots of paint. This process is known as the 4 color screen printing process.

Each of these colors plays a special role. They mix back together on the fabric to bring the original picture back to life. It’s a bit like a dance of colors, where each step is carefully planned to make sure the final performance is a showstopper. For example, to get the right shade of blue, you’ve got to figure out just how much yellow to throw into the mix. It's all about finding the perfect balance.

Now, this method does ask for a bit more from your wallet, especially when you're working with dark shirts. But here's the kicker: the only way to get that classic, crisp image – like the ones in magazines – is with a fancy technique called 4 color process printing. When we print on T-shirts, it’s a bit more like putting on a magic show, using tricks to make the colors pop in a way that feels right at home on the fabric, making it comfy and soft to wear.

Grayscale Printing

Let's dive into a straightforward method that turns colorful pictures into single-shade wonders, be it grayscale printing or halftone. Imagine taking those vibrant photos or artwork, filled with all shades of colors, and turning them into a one-color masterpiece. While black ink on a light shirt is a classic look, you can actually pick any color you like for this magic to work.

Remember those black-and-white photos in newspapers? We're using a similar trick to put those one-color halftones right onto T-shirts. The secret to getting a clear and detailed image is all in the dots per inch – the more dots, the sharper the picture.

This technique is the best way to get black and white, or even full-color photos, onto your clothes without breaking the bank. White T-shirts work the best for this, giving you a print that not only looks great but feels soft to the touch. It's like wearing your favorite photo, but even cooler.

Simulated Process Screen Printing

Mixing up the usual four-color printing with some special spot colors can make your T-shirt stand out in a crowd. Sometimes, we add these spot colors to the mix to nail the exact shades of the original picture. It's like giving the shirt an extra pop of color where it really needs it, especially when the regular printing can't get a particular color just right. You can throw in as many of these special colors as you want, but keeping it simple usually works best.

Just a heads-up, though: going for this mix-and-match approach might cost a bit more than the usual way of simulated process screen printing. Why? Because it can get pretty detailed with the artwork and might need more screens to get everything just right. This method is a favorite for bringing complicated designs to life on dark shirts. It can make some really cool pictures come alive on fabric, but you've got to know a bit about making the artwork. How the shirt feels in the end depends on the design and if there's a base layer used for printing on dark colors. It's all about making the T-shirt feel as good as it looks, adding a personal touch.

6. The Advantages of Screen Printing

Screen printing is a super cool way to make your custom shirts or promotional stuff stand out. Let's talk about why it's the best choice for lots of projects.

Handling Big Orders is a Breeze

First off, screen printing is awesome for big orders. Thanks to some help from machines, this process can zip through thousands of shirts in no time. So, if you've got a huge order, screen printing can handle it like a champ, especially with the fancy machines and the pros who know how to use them.

It Works for Any Design

Another great thing about screen printing is its flexibility. Whether your design is super simple with just one color or really detailed like a photograph, screen printing can make it happen. This means no matter what your design looks like, screen printing has got your back.

Made to Last

One of the best parts about screen printing is how long it lasts. When someone who really knows their stuff does it, your design will stick around for years, even if you wash it a lot. Ever seen those old rock band shirts that still look cool? That's screen printing for you. It's a way to make sure you're getting something that's going to last.

Looks Awesome

Screen printing can make designs look really amazing. Whether you want something that grabs everyone's attention or something more low-key, screen printing can do both. It's known for making colors pop and giving a sharp finish, turning a plain item into something eye-catching or a perfect way to spread your message.

7. Screen Printing Problems and Solutions

Screen Printing Image Concerns

i. Bubbling: Air Bubbles on Solid Prints

| What Causes It |

Solutions |

| Rushing the printing process can trap air, leading to bubbles. |

Slowing down the squeegee can make a big difference. |

| Overloading the screen with ink. |

A firmer squeegee blade helps control ink application. |

| Using ink that's too thick. |

Thinning out the ink with a specialized additive.

|

| Ink agitation from high-speed mixing introduces air bubbles. |

Give the ink time to settle after mixing or mix at a slower speed to avoid air entrapment. |

ii. Contamination: Unwanted Spots in Your Print

| What's Behind It? |

How to Fix It |

| Lint or dust trapped on the screen. |

Regularly cleaning the screen and the workspace, and maintaining a higher humidity level can prevent dust from settling. |

| The printing surface itself might be dirty. |

Handle the material carefully to avoid transferring oils or debris, and clean the surface before printing to ensure it's free of contaminants. |

iii. Ink Spreading: When Edges Aren't Crisp

| The Cause |

How to Fix It |

| Ink that's too runny. |

Adding a hardener to the ink to improve consistency. |

| Too much pressure from the flood coat. |

Adjusting the flood bar to avoid contact with the screen during flooding. |

| A worn or overly rounded squeegee. |

Keeping the squeegee sharp for precise ink application. |

iv. Ink Leakage Around the Image

| The Cause |

How to Fix It |

| The presence of foreign materials underneath the stencil near the edge of the image. |

Ensure the underside of the screen is clean to prevent ink from seeping out. |

| Using ink that is too thin. |

Consider adding an ink hardener to thicken the ink and reduce leakage. |

V. Blur and Ghosting Effects

| Root Causes |

Solutions |

| A gap that's too small between the product and the screen, known as insufficient snap-off. |

Adjust the off-contact distance to about the thickness of a nickel, ensuring a consistent gap across the entire screen. |

| The fixture holding the product isn't aligned with the product's height, causing the squeegee to move unevenly. |

Ensure the fixture and product are at equal heights. If adjustment isn't possible, tilting the squeegee at a 20-degree angle may help manage the transition from fixture to product. Slowing down the print speed can also mitigate this issue. |

Vi. Blurred and Distorted Images

| Root Causes |

Solutions |

| The press sheet may adhere to the mesh due to static electricity. |

Reduce the printing speed, enhance the vacuum, and increase snap-off distance. Adding an anti-static agent to the ink, grounding the table bed, and using static eliminators can also be beneficial. |

| Excessive printing speed. |

Adjusting the squeegee speed can also help in creating a more crisp image. |

| Bubbles in the ink resulting from high-speed mixing. |

Allow time for bubbles to dissipate or lower the mixing speed. |

Vii. Addressing Streaks in Screen Printing for Consistent Image Quality

Challenge Overview: A common problem in screen printing is the appearance of streaks, characterized by a variance in density across the image that aligns with the direction of the printing stroke.

| Primary Causes |

Effective Solutions |

| Damage to the squeegee blade, such as a nick or cut. |

The squeegee blade should be sharpened or replaced to ensure a smooth, consistent application of ink. |

| Imperfections on the flood/coater blade. |

Similarly, the flood/coater blade requires attention—either sharpen it or opt for a replacement. |

| Nicks or scratches present on the press bed. |

Address any imperfections on the flood bar by smoothing, filling in gaps, or replacing it entirely to avoid disrupting ink application. |

Viii. Tackling Mottling for Uniform Ink Absorption

Challenge Overview: Mottling presents as uneven ink absorption by the substrate, leading to areas of differential appearance.

| Primary Causes |

Effective Solutions |

| The quality of the stock is subpar. |

Switch to a higher quality stock and consider applying a clear-coat to the stock before printing. |

| The ink film applied is insufficiently thick. |

Increase the thickness of the ink film by using a coarser mesh. |

| The ink used is too thin or lacks opacity. |

Enhance the ink's pigmentation to achieve the desired opacity and coverage. |

ix. Preventing Ink Drying in Screen for Flawless Printing

Challenge Overview: Ink prematurely drying within the screen can lead to incomplete or patchy image areas.

| Primary Causes |

Effective Solutions |

| The ink viscosity is too high, facilitating premature drying. |

Regularly clean out the stencil and adjust the ink's viscosity using a solvent. |

| Elevated ambient temperatures exacerbate ink drying. |

If ambient temperatures are a concern, use a retarder to slow the drying process. |

| The squeegee's rubber is either blunt or too soft. |

Opt for a squeegee that is either sharper or made from a harder rubber to ensure consistent ink application. |

X. Ensuring Complete Ink Coverage in Multicolor Prints

Challenge Overview: A significant issue arises when a second color fails to completely cover the first, known as second color refusal.

| Primary Causes |

Effective Solutions |

| Excessive silicone in the first layer of ink. |

Reevaluate and potentially change the first ink formulation to reduce silicone content. |

| The second color ink is too thick. |

Adjust the second color ink's viscosity for better coverage. |

| Solvent from the first ink layer interferes with the second. |

Ensure the first ink layer has dried completely before applying the second color to prevent solvent interference. |

8. The Future of Screen Printing

Historical Context and Evolution

Screen Printing History

Screen printing is an art that's been around for ages. Some people even say it started with simple stencils on the walls of ancient caves.

Where screen printing really began is a bit of a mystery, but many think it started in China around the time of the Song Dynasty in 960AD. This was a time when art was really taking off, and they came up with a way to print intricate designs on fabric using mesh and stencils.

This technique didn't stay in China for long; it quickly spread to other parts of Asia. In Japan, for example, artists made the mesh from human hair and used hard brushes to get the paint on. Later on, silk became the go-to material for the mesh, and that's when people started calling it "silkscreen printing."

European Debut of Screen Printing

Silkscreen printing didn't make its way to Western Europe until the 18th century. It was the European traders, coming back from their trips along the Silk Road, who brought this cool printing method and the needed materials back home.

In France, artists started using silkscreens stretched over frames to print their designs onto fabric. This method became even more popular during the Industrial Revolution, as factories began using it to make loads of wallpapers and fabrics.

The first "modern" version of screen printing was patented in 1907 by an Englishman named Samuel Simon. His technique involved making stencils on a piece of cloth called bolting cloth, which was then stretched over a wooden frame. Although his method became the go-to in Europe, it was still something only the rich could afford.

Around the 1910s, a group of three guys figured out how to use chemicals that react to light to make the screen printing process even better. This invention of photo-imaged stencils was a game-changer for the industry. We still use similar methods today, just with safer chemicals.

The Boom of Screen Printing in the 1960s

Back in the 1960s, when politics was heating up, the way ideas spread through mass-produced media was super important. Screen printing was a go-to method for making bold and memorable images on posters, signs for protests, and even clothes.

Even though screen printing got better over time, it was still pretty tough to do. That all changed when Michael Vasilantone came up with his rotary multicolored screen printing press. This invention really made screen printing take off in making clothes. It was first made for bowling shirts, but t-shirt makers were quick to pick it up too.

During the '60s, screen printing was huge in the Pop Art scene. Famous artists like Andy Warhol used it to make colorful, repeated images that became really famous, like the Marilyn Monroe pictures and those Campbell's Soup cans.

Screen Printing Now: How Things Are Today

Screen printing's story is far from finished—it's actually become one of the go-to methods for printing on garments. Nowadays, artists are mixing up digital designs with age-old screen printing techniques to create truly unique pieces of wearable art.

Looking for top-notch custom screen printing? GiftAFeeling has exactly what you need. Our range of t-shirts, hats, and hoodies are the perfect way to make your small business or promotional event really pop. Contact us today for a customized quote.

The Importance of Screen Printing in Today's Market

Screen Printing Statistics

Is the Screen Printing Industry Growing?

The global industrial screen printing market size is on an upward trajectory. Estimated at $695 million in 2023, it's expected to climb to $1,176.2 million by 2030. That's a steady growth rate of 7.8% over the forecast period.

Exploring Global Screen Printing Industry Statistics: Insights from Different Regions

North America

North America is at the forefront of the industrial screen printing world, snagging over 30% of the global market share in 2023. This region is where you'll find big names in the screen printing game like Vastex International and M&R Screen Printing Equipment. So, what's driving this boom? It's all about the growing love for custom-made stuff, the ease of shopping online, and the booming car industry. It shows that in North America, the demand for personalized and convenient products is really pushing the screen printing industry forward.

Europe

Europe takes the silver medal in the industrial screen printing market, holding over 25% of the worldwide share in 2023. The region is packed with some big names in screen printing, like SAATI and KIWO. What's making Europe's market grow? Well, more people want products made just for them, online shopping is more popular than ever, and there's a bigger demand for gadgets and home appliances.

Asia Pacific

This region is on a serious growth spurt, with over 20% of the global market in 2023, and it's expected to zoom ahead with a growth rate of over 17% in the next few years. What's behind this boom? A growing economy, a population that's increasing, and a rising appetite for all sorts of consumer goods. Asia Pacific is really setting the pace in the screen printing market.

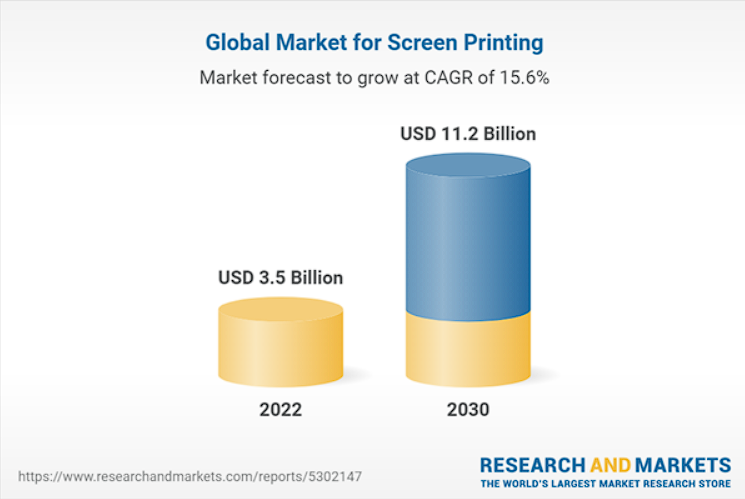

Global Screen Printing Market Expected to Reach $11.2 Billion by 2030

The Global Screen Printing Market is on a remarkable journey, aiming for a $11.2 billion milestone by 2030. Starting from a solid foundation of $3.5 billion in 2022, this sector is navigating through an impressive growth trajectory, with expectations to flourish at a 15.6% annual growth rate through the span of 2022 to 2030.

(Credit: Research and Markets)

The U.S. Screen Printing Market Is Valued at $952.6 Million, with China Projected to Grow at a 22.5% (CAGR)

The screen printing market within the United States is currently valued at an estimated 952.6 million USD for the year 2022. The People's Republic of China, ranking as the world's second-largest economy, is anticipated to attain a projected market size of 3 billion USD by the year 2030, following a compound annual growth rate (CAGR) of 22.5% throughout the analysis period spanning from 2022 to 2030. Other significant geographical markets include Japan and Canada, each predicted to experience growth rates of 8.8% and 12.8% respectively during the period from 2022 to 2030. Within the European context, Germany is expected to witness a growth rate of approximately 10.7% CAGR.

Source: Research and Markets

Exploring the Future of Screen Printing in the Growing Digital Landscape

Technological Innovations Keep Screen Printing Competitive Amidst Digital Printing's Growth

Recent tech advancements are making screen printing even better, keeping it up to speed with the growing popularity of digital printing. For those who love screen printing, there's no need to worry. Your favorite printing method isn't disappearing anytime soon. Even though digital technology has improved a lot, making direct-to-garment (DTG) printing a good choice for small orders, screen printing still wins for big orders and the wide variety of items you can print on. Because DTG and screen printing each have their own special perks, print shops are going to keep using both to make sure they can take care of all their customers' needs.

Pre-Press for Screen Printing Made Simpler Than Before

Making screen printing ready before actually printing has gotten a lot easier. The main steps of getting ink onto the material haven't changed much over the years and probably won't change much anytime soon. But, the technology for the pre-printing steps in screen printing shops is getting better. Now, there are computer-to-screen systems that help skip some steps, like not needing to print film positives. This helps make and set up high-quality stencils for clearer prints. Also, there's now automation for coating screens, which means it's easier and more even when applying the emulsion to screens than before.

What is the Future of Screen Printing?

Screen printing has really changed since the 1960s when it started getting modern touches. Now, we have cool things like computer tech, special inks that do amazing effects, machines that work on electricity, and special drying units that were hard to even dream of back in the day. The cool thing about screen printing is that it is always changing and growing. People who do screen printing are always thinking up new ways to make their prints stand out and look awesome. It is exciting to think about what new gadgets and ideas will pop up next in screen printing.

9. How Silk Screen Printing Works: A Step-by-Step Guide to Design Creation Conceptualizing and Digitizing Your Text Go Here

Screen Printing Process Step By Step

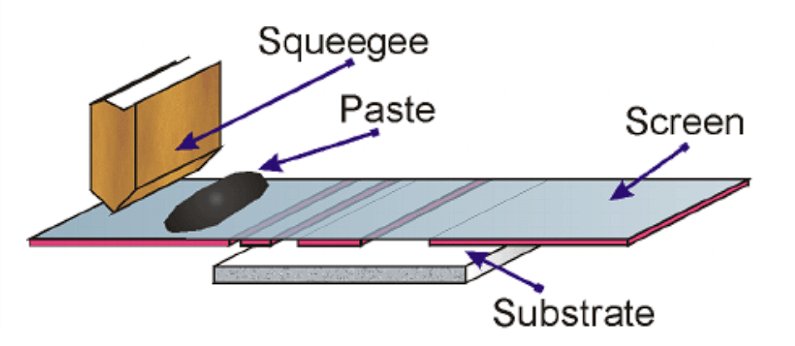

The screen printing process encompasses a method wherein a stencilled design is transferred onto a flat surface utilizing ink, a mesh screen, and a squeegee.

Step 1. Design Creation

The initial phase involves preparing the desired design for printing. This can be accomplished by either manually drawing the image or by printing the image from a computer onto a transparent acetate film, which will serve as the basis for creating the screen. It is imperative that the image is rendered in black.

Step 2. Screen Preparation

Source: (Credit: Instructables)

Choosing the correct mesh count

Once the design is ready for printing, the next step involves selecting the appropriate screen and mesh count. The mesh count refers to the number of fibers per square inch and plays a crucial role in the screen printing process, depending on the intricacies of the design:

- For printing finer details while still achieving an even spread of ink, a screen with a higher mesh count is preferred.

- Screens with a lower mesh count feature wider openings, allowing for a heavier flow of ink, suitable for less detailed images.

- Upon choosing the mesh screen, it is then coated with a layer of light-sensitive emulsion.

Applying emulsion

There are primarily three types of emulsions used in this process:

- Diazo emulsion is the more budget-friendly option, though it requires a longer exposure time and is less suitable for intricate designs.

- SBQ-based emulsion, on the other hand, does not require mixing, sets very rapidly, and, while it is more costly, it is ideal for detailed prints.

- Dual-cure emulsions offer a middle ground, combining elements of Diazo and SBQ. They need to be mixed, but their overall cure time is shorter than that of Diazo, and they are less expensive than SBQ-based emulsions.

Step 3. Exposing the Emulsion

Photo emulsion is a liquid that undergoes a reaction when exposed to UV light, causing it to harden. This property is utilized in the screen printing process, where the photo emulsion is applied to both sides of the mesh using either a scoop coater or a squeegee. It is imperative that the emulsion coating is applied uniformly and thinly, ensuring that there are no gaps or uncoated areas. This step of the process should be conducted with caution, away from UV light sources, and preferably in a room with low lighting.

Step 4. Creation of the Stencil

(Credit: Metmuseum.org)

Once the emulsion is dry on the flat side of the screen, place the transparency upside down on it. Then, place a piece of glass on top to ensure the transparency stays flat against the screen. Now, your screen is ready to be exposed. You can use sunlight by going outside, or you can use lamps to expose the screen to the light source. When you expose the screen with the transparency to the light, a reaction occurs. The areas hit by the light harden and won't wash off, while the parts that are still soft can be washed away. Next, rinse away the soft emulsion with water. You have now successfully transferred your design onto the screen.

Step 5. Printing the Design

(Credit: Metmuseum.org)

The fabric that you want to print on is laid down flat on the printing table. Then, you carefully place the screen on top of the fabric where you want your design. Apply a thick layer of ink in your chosen color on the screen. Using a squeegee, you pull the ink all the way across the screen to cover the whole design. What happens is the ink goes through the open parts of the stencil onto the fabric underneath, leaving behind a print of your design in ink. You print one color at a time, so if you want a design with multiple colors, you'll use different screens for each color.

Step 6. Heat Curing and Finishing

The transferred print on the item fully dries with the aid of a dryer. Subsequently, it is essential to wash and inspect the final product for any residual ink before it is marketed. Additionally, the mesh screen must be cleaned with chemicals to ensure it is ready for future use.

10. Frequently Asked Questions (FAQ) Section

1. What is the estimated value of the global market for screen printing?

In 2022, the global market valuation for screen printing was approximately $3.5 billion.

2. What is the growth rate of the global market for screen printing?

The screen printing market is expanding at a rate of 15.6%, expected to reach a valuation of $11.2 billion by 2030.

3. What is the forecasted size of the global market for screen printing?

By 2030, the global market for screen printing is forecasted to be valued at $11.2 billion.

4. What will be the CAGR of the screen printing market?

From 2023 to 2030, the screen printing market is anticipated to grow at a compound annual growth rate (CAGR) of 7.9%.

5. Which region will lead the market?

During the forecast period, North America is predicted to lead the screen printing market.

6. What are the major factors driving the screen printing market growth?

Key drivers of market growth include the rising demand from end-use industries, the increasing application of screen printing inks, and the effects of growing population and urbanization.

7. What is the best angle for screen printing?

Most printers will tell you that a 45-degree angle with the squeegee is just right for a clean print. Though, some prefer it a bit steeper, around 70 to 80 degrees. A handy tip is to align the squeegee with your nose to keep that angle consistent.

8. What is the angle for screen printing?

Aiming for a 45-degree angle typically hits the sweet spot for screen printing.

9. What is the minimum thickness for screen printing?

Keep your lines thicker than 0.5mm for fabric and 1pt for paper. And for text? Stick to sizes larger than 18pt on fabric and 12pt on paper to keep everything readable.

10. What is the best size for screen printing?

For adult tees, an 11” x 11” design usually looks awesome. For the younger crowd, scaling it down to about 9” x 9” works great.

11. How much pressure do you apply when screen printing?

Just a gentle push with the squeegee is enough. You want to press the ink through without making the squeegee's edge bend.

12. What is the standard mesh size for screen printing?

The go-to mesh counts are 110 and 156. The 110 mesh lays down a nice thick layer of ink, perfect for those bold letters and simple color blocks.

13. What are the parameters of screen printing?

When we talk screen printing, we're looking at a few key settings: the distance the screen snaps back, the angle and speed of the squeegee, and how much pressure it's pushing with.

14. What is the best temperature for screen printing?

When you’re printing on t-shirts, you’ll want to heat the ink between 270 and 330 degrees Fahrenheit. This makes sure the design really sticks and lasts a long time.

15. What size dot for screen printing?

When we're talking dots in screen printing, for shirts, we use dots that are between 60 and 90 lines per inch. But if we’re going for something super detailed, like art, we go finer, up to 150 lines per inch.

16. Which garment decoration methods are most recommended for clients?

Definitely keep embroidery and screen printing on your list—they're classics for a reason. But, don't miss out on the cool stuff like sublimation, direct-to-garment printing, and heat transfers. Mixing these up can really wow your clients.

17. Can you explain the distinctions between screen printing, sublimation, and transfers?

Think of screen printing as the old-school way of pushing ink onto clothes through a screen. Sublimation? It's kind of like a magic trick where ink turns into gas with heat and dyes the fabric. And heat transfers are pretty much what they sound like—printing a picture and then ironing it onto your shirt.

18. How are embroidery and screen printing most commonly priced?

It's all about quantity—the more you order, the less you pay per piece. Embroidery costs depend on how many stitches you need, and screen printing gets pricier with more colors. If you're only making a few items, there might be cheaper ways to go.

19. What kind of artwork is required by a distributor for each type of decoration method?

Always aim for the best quality art you can get. For embroidery and vinyl cuts, you'll want vector files. Screen printing can work with vectors or high-quality pictures. Vectors are great because you can make them bigger without losing any detail, unlike pictures which can get blurry if stretched too much.

20. Why does the cost of screen printing increase for dark-colored garments?

It's like painting your room—if you're going from dark to light, you need a primer first. Screen printing on dark clothes needs a base layer so the real colors stand out bright and clear.

21. Will screen printing ink wash out?

If your shirt's screen printed by experts who use the right ink and process, it shouldn't fade in the wash. Getting the heat and timing right makes your design stick around for the long haul.

22. How long does screen printing last?

A screen-printed tee can handle about 40 to 50 washes before showing signs of wear. The ink they use goes deep into the fabric, making your print last a good while.

23. Can screen printing be done on any material?

Most of the time, screen printing's done on fabric and paper. But, with the right kind of ink, you can print on almost anything—wood, metal, plastic, and even glass.

24. What is the process of screen printing?

Screen printing is all about pushing ink through a mesh screen to get your design onto a surface. While it's usually done on fabric or paper, you can also print on materials like metal and glass with the right setup.

25. Is screen printing good quality?

Yep, screen printing is top-notch. The colors come out bright and bold, and the print itself is super durable. It's best for designs that aren't too complicated.

26. Why is screen printing so expensive?

Screen printing takes a lot of hands-on work and attention to detail, which can add up, especially for small batches. Setting everything up takes time, making it pricier than quicker methods like digital printing.

27. What material is best for screen printing?

Cotton and cotton blends are the go-to for screen printing. Cotton's great because it soaks up the ink well, making for a solid print. Plus, it feels nice whether it's knitted or woven, keeping you cool or cozy depending on the weather.

28. Is screen printing permanent?

Yep, if it's done right, a screen print can last as long as your T-shirt does. We've gotten really good at making screen prints stick around thanks to better paints and techniques.

29. Does the screen print crack?

Sometimes, screen prints might crack after a while, which changes how they look. It's pretty common.

30. Can you screen print on 100% cotton?

Absolutely! Cotton is awesome for screen printing. It loves soaking up the ink, and it's both easy on your wallet and great for dealing with heat and static.

31. What are the main features of screen printing?

Screen printing is super versatile. You can print on lots of different stuff, no matter their shape or size, and you've got loads of inks to choose from. The best part? The colors come out really bright and the print lasts a long time.

32. How many types of ink are used for screen printing?

We usually use three main types of ink: discharge, plastisol, and water-based. Each has its own special uses and needs a bit of skill to work with.

33. Can cotton be screen printed?

Definitely! Cotton is perfect for screen printing. It's great at grabbing onto the ink, and it's both affordable and good at handling heat and avoiding static.

34. Which fabric is suitable for screen printing?

Cotton and its blends are the go-tos. Cotton's great because it really takes to the ink well, and depending on how it's made, it can be super soft or keep you cool when it's hot and warm when it's not.

35. Which film is used in screen printing?

In screen printing, we use a special kind of film, often referred to as 'Acetate', 'Film', or affectionately, 'Possies'.

36. What are the three types of screen printing presses?

There are three main buddies in the screen printing press family:

The flat-bed.

The cylinder.

The rotary press.

37. What are the characteristics of screen printing?

Screen printing's great because it lets you print on all sorts of materials, no matter their shape or size. You've got loads of inks to choose from, which means colors can come out really bold, the finish can be super solid, and the designs stay bright for ages.

38. Does screen printing require heat?

Yep, if you're using water-based inks for screen printing, you gotta heat them up to make sure the design sticks on the fabric. If you skip this, your masterpiece might fade away quickly.

39. What are the 4 colors in screen printing?

In screen printing, we use a cool trick called CMYK. That stands for Cyan, Magenta, Yellow, and Black. With just these four, you can create almost any image on light shirts. It's like magic with just a few colors!

40. What is CMYK screen printing?

CMYK printing is awesome for getting full-color pictures onto white shirts. It mixes four colors—cyan, magenta, yellow, and black—to copy your favorite images using just four screens. Pretty neat for shirts, right?

41. What is frequency in screen printing?

Frequency in screen printing is all about how many little dots (halftone cells) we can fit in an inch. The more dots, the sharper the picture. And the screen angle? It's just the way we tilt those dots to make the image look just right.

42. How much water does screen printing use?

Screen printing can use a lot of water, like 50-60 liters for each meter of fabric. But digital printing? It's way more water-friendly, using less than 2 liters per meter. Big difference, especially if you care about saving water.

43. What's the difference between screen printing and digital printing

Screen printing offers a more vibrant finish, particularly when applied to darker surfaces, due to its method of layering inks. In contrast, digital printing is more adept at producing detailed work. This is attributed to the application of thinner layers of ink, ensuring that the final print achieves greater precision.